Spray applications in agriculture

It comes as no surprise that the application of crop protection products is one of the biggest expenses to a farming operation. To maximise return on investment, producers need to ensure that pesticides remain within the paddock and hit the intended targets. This requires a few things; relevant spray equipment and machinery, suitable weather conditions, and the use of an appropriate adjuvant. Effectively managing these will reduce any risk of off-target damage and potential spray drift into surrounding areas.

Importance of managing spray droplet size

In converting the solution into spray droplets, the atomisation process and droplet fate are specifically dependent on the solution’s physical characteristics, spray volume, nozzle type and pressure, and conditions at the time of application. Ensuring that the appropriate size and distribution of spray droplets are met, is critical in managing drift. Droplets smaller than 150 microns tend to be the most prone to drift, as these fall far slower than larger droplets. A simple explanation for this is that they don’t have the weight to overcome air resistance, increasing susceptibility to float with wind currents. These droplets are commonly referred to as ‘driftable fines.’

Off-target herbicide movement not only affects the surrounding environment but also reduces weed control in the target area. This comes at both an environmentally and economically cost to a producer, as they may be required to do another spray pass, costing more in time and product, or be ordered to compensate neighbours for damages. With pesticide use increasing, public awareness of the associated risks of off-target movement has created the need to re-evaluate weed control and pesticide application practices.

Understanding droplet size

Understanding the correct terminology regarding droplet sizes can assist producers in assessing the data supplied by chemical, equipment or machinery manufacturers. This will contribute to bettering producer spray application knowledge to minimise the adverse impacts that wrongful practice may cause.

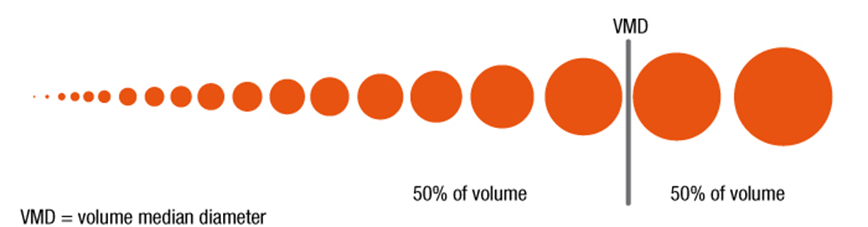

VMD or Dv0.5

- Volume median diameter (VMD) refers to the midpoint droplet size

- Indicates that one half of the spray volume is in droplets smaller than the median, whilst the other half consists of larger droplets (see Figure 1)

- Ideal range =

Dv0.1

- Indicates that 10% of the spray volume is in droplets smaller than this value

- Major contribution to the production of driftable fine droplets

- Primarily used to estimate the relative driftable portion of sprays

- The smaller this number, the more potential there is for drift as more driftable fine droplets are present

- Larger number > smaller number

- Ideal range =

Dv0.9

- Indicates that 90% of the spray volume is in droplets smaller than this value

- Or 10% larger

- The larger this number, too much of the spray volume is taken up in fewer, larger droplets

- Ultimately, this reduces spray coverage and efficacy because there aren’t enough droplets to adequately cover all surfaces

- Ideal range =

Relative Span (RS)

- A measure of the width of a droplet spectrum around the Dv5

- RS = (Dv9 – Dv0.1)/Dv0.5

- The smaller this number, the less variation there is between the size of the droplets in the spray spectrum

- Ideal range =

- Consider 2 treatments that both have a Dv5 of 300 microns

- Treatment 1; Dv9 = 800, Dv0.1 = 150

- RS = (800-150)/300 = 2.2

- Treatment 2; Dv9 = 600, Dv0.1 = 200

- RS = (600-200)/300 = 1.3

- Despite same Dv5, Treatment 2 has much less variation amongst droplets, ensuring less drift potential and greater coverage

- Treatment 1; Dv9 = 800, Dv0.1 = 150

Agricultural products that claim to reduce drift potential by increasing the VMD or Dv0.5, should only be considered if supporting data shows a significant reduction in the Dv0.1 without adversely increasing the Dv0.9 or RS.

Where does Spraytec fit in

Spraytec continues to view itself as a pioneer in the phytostimulant space, producing products that exhibit a proprietary blend of ingredients. Composition revolves around chelated nutrition, phosphites, and refined application technology. Our two products designed for all-year-round use, Fulltec and Fulltec Max, have shown exemplary performance in complementing pesticide spray applications. Their ability to enhance efficacy and operations creates a practical experience for producers. Either product is characterised by anti-drift properties that work to ensure an ideal droplet spectrum of between 200-400 microns. Coinciding with reduced droplet surface tension, this guarantees improved spray coverage.

Current comparable products

In terms of comparisons to comparable products in the industry, Fulltec and Fulltec Max have drawn similarities to other drift retardants such as Li700®, Hasten®, Dead Sure® and Uptake®.

Analysis and results in Australia

Last year, the Australian National Centre for the Public Awareness of Science (CPAS) and the University of Queensland conducted a wind tunnel assessment using Fulltec and Fulltec Max. Results were compelling and can be derived below.